Riken models, GD-A2400 / SD-2500 / SD-2600 / SD-2700 are designed to specifically monitor high boiling point solvent vapours. The design detects solvent vapours inside furnaces, and process drying machine exhaust ducts.

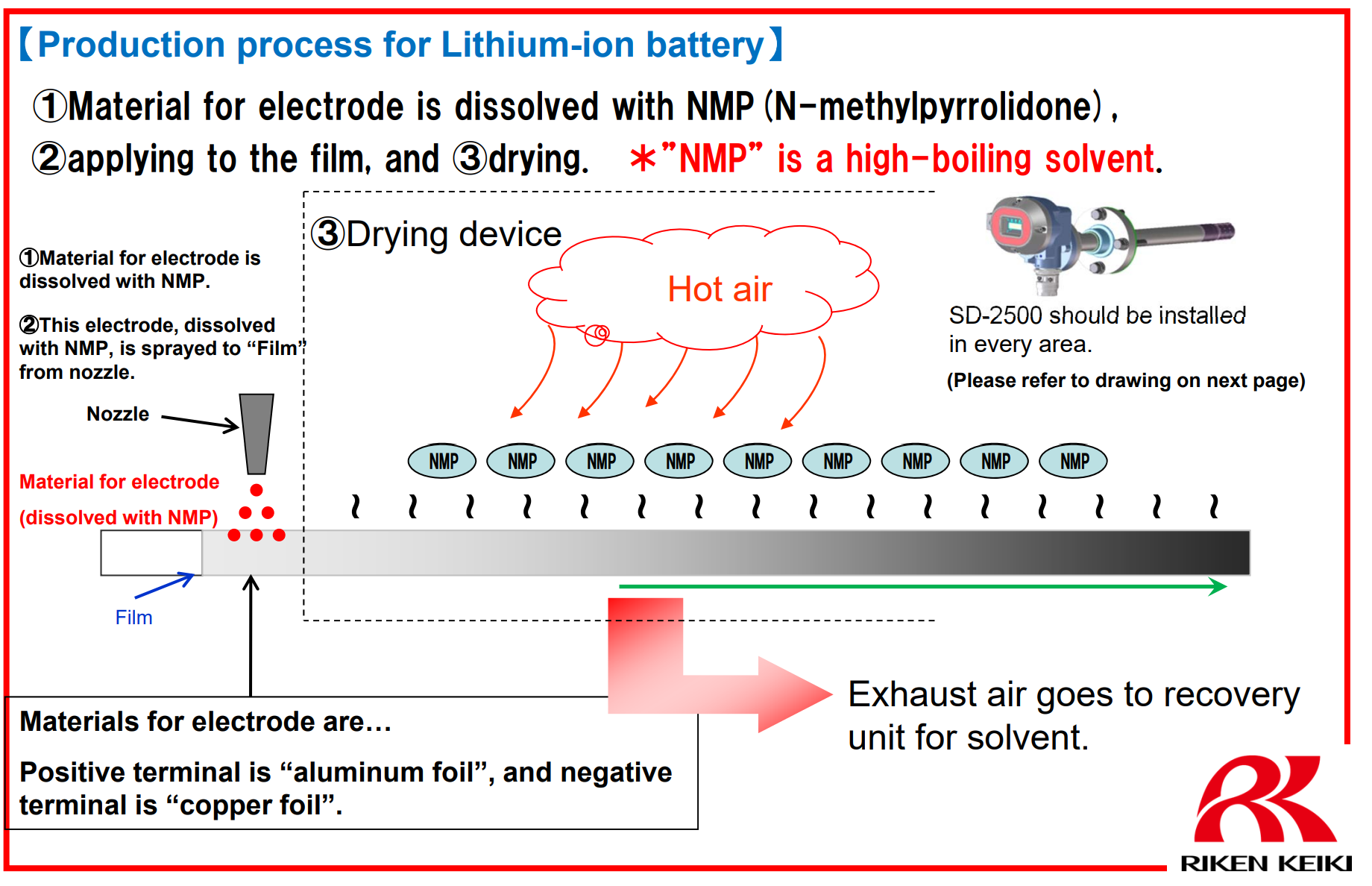

SD-2500 series are used extensively to detect NMP in the manufacturing of Li-ion battery cells.

Ideal for Li-ion Battery Cell drying room applications.

Ideal for direct insertion to ducts & furnaces.

Ideal for high boiling point solvents.

ATEX: Ⅱ1G Ex d ⅡC T3/T2 Ga IECEx: Ex ia ⅡC T3/T2 Ga.

Easy to set up & maintain.

The Riken Keiki SD-2500 is designed to be used inside furnaces and process machine exhaust ducts, to monitor high-boiling solvents.

The SD-2500 features a long sensor head (250mm in length), operating in high temperatures 0 to 160℃ (SD-2500) or 0-200℃ (SD-2600), flameproof enclosure, and smooth operation with a control key.

It is used extensively in Li-on production facilities and Giga Factories, to measure N-Methyl-2-pyrrolidone (NMP) (C5H9NO) in exhaust ducts located in drying machines. See article NMP monitoring in Li-ion Drying Applications.

| Category | Fixed gas detector |

|---|---|

| Type | Stand-alone gas detector |

| Detection gas | NMP (N-methylpyrrodidone), High Boiling Point Solvents |

| Principle of detection | Catalytic combustion |

| Detection range | 0-100 %LEL |

| Sampling method | Diffusion |

| Display of alarm | Gas alarm, Trouble alarm |

| Explosion protected construction | Flameproof enclosure |

| Approvals | ATEX, TIIS, CE |

| Power source | DC24V |

| Dimensions | Main body: 148(W) x 161(H) x 88(D) mm Insert part: φ34 x 250 mm |

| Weight | Approx 4.6kg |

| Operating temperature range |

Main body: 0 to 50 ℃ |

We are able to provide products and advice usually within short timescales. For product advice, servicing and enquiries, please contact our experienced team: