Calorific Value is the amount of energy generated by perfect combustion of fuels. In the current Energy Saving environment, it is important to make progress in improving energy efficiency at all levels.

Using a Calorimeter at Electricity Generation Plants and Gas Energy Distribution Stations, can assist enormously to increase efficiency as well as reducing environmental impacts.

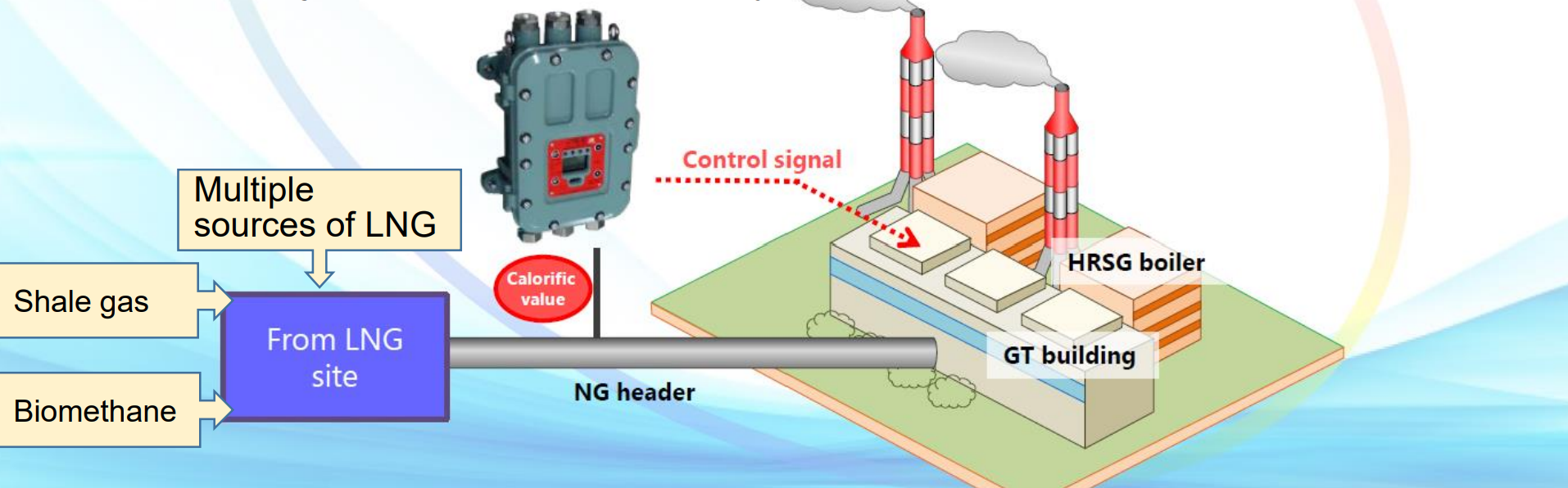

As an example, variations in the Calorific Value of LNG gas used on Power Stations, caused by an increased diversification of sources, means it is important to measure and adjust the air / fuel ratio burnt in the turbines. This is becoming even more important with the increasing adoption of Shale and Biogas.

Highly accurate gas Calorific measurements leads to higher cost savings.

Industries fastest response time means more efficient fuel gas usage & lower fuel costs.

Highly accurate across the entire range.

Flexibility for any application.

Ideal for Hydrogen Economy.

Suitable for hazardous areas & Hydrogen.

The Riken Keiki OHC-800 is a fixed gas Calorimeter in a flame-proof enclosure (explosion-proof class: Ex dⅡB+H2 T4). It is designed for continuous, measurement of the “Calorific value,” “Density,” and “WOBBE index” of various fuel gases.

Examples of these include natural gas, coke oven gas, blast furnace gas, converter gas as well as biomass gas, and biogas.

The OHC -800 is based on Riken’s Patented “OPT-SONIC” Calculation technology, the technology uses and Optical as well as a Sonic sensor and combines the two measurements. This minimises interference from other gases as well as enabling high accuracy and reliable measurements.

The OHC-800 can change displays between “Calorific Value", “Density” and “WOBBE” index with a simple press of a button. Laborious calculations are not required, a self diagnosis function is included. It includes a fault diagnostic that prevents the Calorimeter being unable to measure gas.

The OHC-800 is extremely reliable as well as having low maintenance requirements. It requires Zero calibration.

There are also very few consumables, the unit is comprised of only 4 x replaceable parts, resulting in low running costs.

The Calorimeter has a fast T90 response time of only 5 x seconds and a repeatability of +/- 0.02MJ/m3, it also has a wide opertating temperature range of -20 to +60 Degrees Centigrade. The OHC-800 demonstrates remarkable temperature characteristics of below 0.10MJ/m3 fluctuation for the temperature change in a day ( <20 degrees C )

The robust structure and explosion proof construction, even for Hydrogen ( ATEX in addition to IECex compliant ), means it can be installed in many different locations. It has a high ingress rating level of IP-66/67.

The types of fuel gases that can be measured depend on specifications.

For information on the types of gases that can be measured please contact Weatherall.

Gas & Biomass Power Plants.

Gas Energy (LNG Terminals etc).

Biogas to Grid.

Oil Refineries as well as Petrochemical Plants.

Iron and Steel works (Coke ovens etc).

LNG Gas Engines for Ships.

| Model | OHC-800 |

| Measuring Principal | OPT-SONIC Calculation through the measurements of refractive index and sound speed |

| Measuring Gas | CH4 basis Paraffinic Hydrocarbon Gases as represented by Natural Gas *1 |

| Measuring Targets | Calorific Value ( Density / WOBBE index selectable |

| Measuring Range *2 | Calorific Value : 25 – 50 MJ/M3 (Gross, 0 Degree C 101.325kPa Converted .

Density : 0.5 -1.5 MJ/m3 (Specific gravity converted ) |

| Measuring Method | Constant –Flow-Rate gas introduction using external sampling devices |

| Display | Full-dot LCD ( with backlight ) 3 colour LED Lamp |

| External Output | 4-20mA DC ( Isolated source current type ) Maximum load current resistance of 300 ohms / RS485 communication |

| FAILURE alarm | Low flow , Sensor abnormality , low light |

| FAILURE alarm display | Lamp (Red) / Content indication on LCD |

| FAILURE alarm contact *3 | No-Voltage contact 1a or 1b De-Energise ( Energise when alarming ) or Energise ( De-energize when alarming ) Contact Capacity of 2A , 30VDC ( resistance load ) |

| Self-diagnostic function | FUNCTION CHECK ( Warm up or Maintenance mode , MAINTENANCE REQUIRED , OUT OF SPECIFICATION |

| Self-diagnostic display | FUNCTION CHECK , OUT OF SPECIFCATION : Lamp (Orange ) / Content indication on LCD

MAINTENANCE REQUIRED : Lamp ( Green ) / Content indication on LCD |

| Self-diagnostic contact | FUNCTION CHECK OUT OF SPECIFCATION No-Voltage contact 1a or 1b De-Energise ( Energise when alarming ) or Energise ( De-energize when alarming ) Contact Capacity of 2A , 30VDC ( resistance load ) : SSR contact , contact capacity of 20W , 240VAC ( resistive load ) |

| Power supply | 100-240VAC +/-10% , 50/60 Hz, Max 18VA or 24VDC +/-10% max

5W ( the setting can be changed to either AC or DC ) |

| Ingress Protection Level | IP66/ 67 |

| Operating temperature | -20 to +60 Deg C ( ATEX / IECEx) |

| Operating Humidity | 95% RH or less ( Non condensing ) |

| Outer Dimensions / Weight | Approx 286(W) x 453 (H) x 150 ( D) mm / Approx 23Kg |

| Explosion Proof Structure | Flame-proof enclosures ( Explosion-proof Class ATEX / IECEx) |

We are able to provide products and advice usually within short timescales. For product advice, servicing and enquiries, please contact our experienced team: